Taking Over The Job Site – Crack Re-injection

There is still an ongoing survey asking about the challenges and problems associated with concrete pressure injection. One of the answers was the situation of taking over the construction site from another contractor, yet someone else writes about the crack re-injection. I put these themes together in today’s episode. I tell you how we run cracks’ re-injection after an earlier unsuccessful try.

Go to Concrete Injection Drilling Calculator now

I suggest what kind of information you should collect and then what to do to repair the leaking crack. I also mention the parameters of the resins that are the best for the correction.

I am convinced that this episode carries a huge amount of information. I would also like to remind you that my crack injection core principles are available to download for free.

The improvement of the injection should be based on these basic principles.

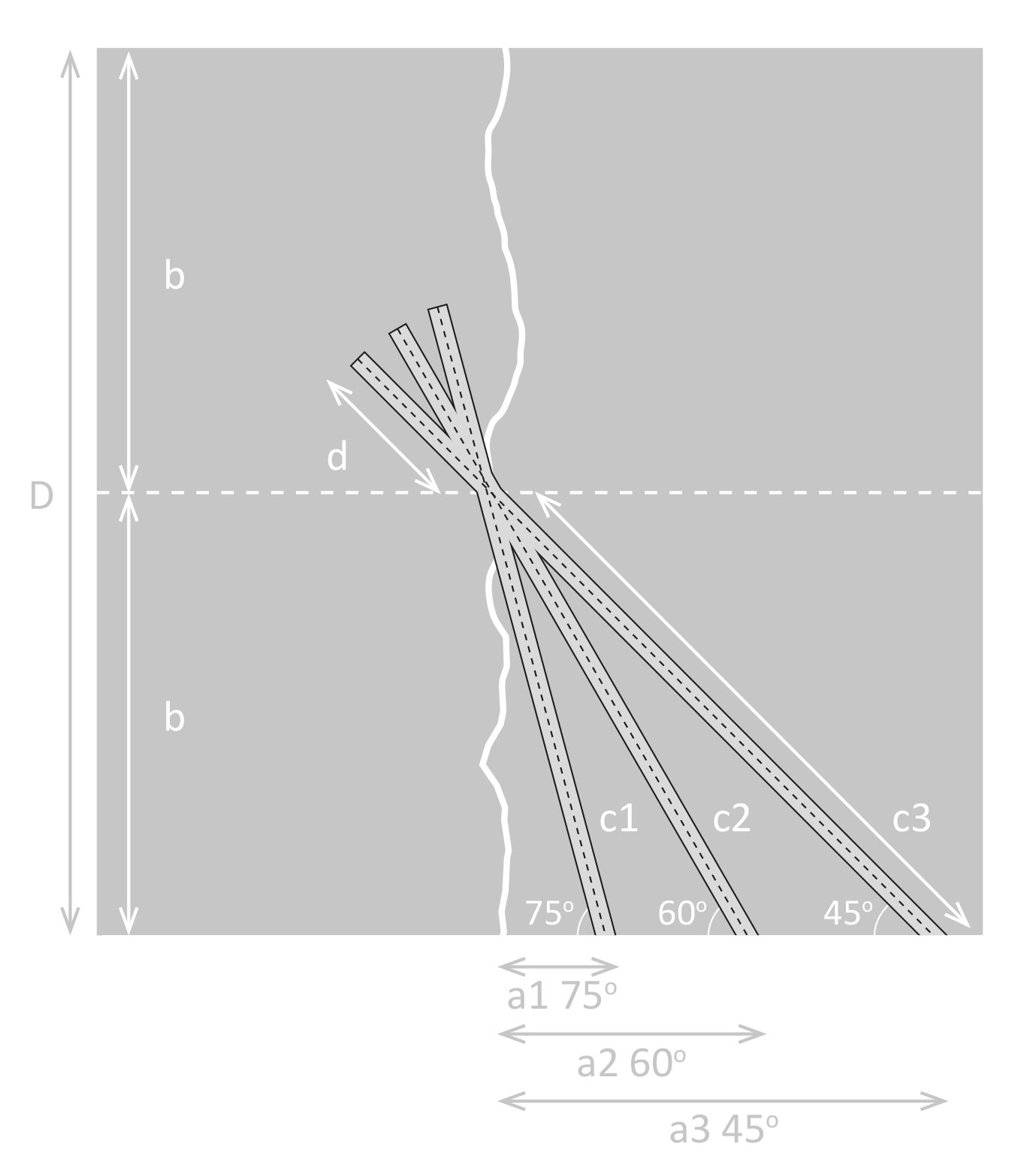

Photos from such projects are not the most beautiful. And at first glance, they are quite a mess. But when you look closely, you can see that the old holes are drilled too close to crack and at the wrong angle, so the old hole’s penetration point is situated very shallowly, close to the concrete surface.

Concrete Injection Drilling Calculator

{loadposition artykulMod3}

Hi, this is Mateusz Furs from the Concrete Injection Made Easy podcast. This is episode number 18. And today, we are going to discuss something that is called taking over of the construction site after another contractor. And today, I’m going to discuss re injection of the crack. But I think I will make a series of episodes under this common title “taking over of the construction site”.

PONIŻEJ WKLEJAMY ROZWINIĘCIE

In the future, I’m going to make another episodes, explain how to re inject the expansion joint, and how to re inject and seal the pipe going through the concrete. So this is my plan to make a series of episodes about re injection of something that has been repaired and injected before. Perhaps you remember when I asked you, you and I send an email to my subscribers to feel and tag the survey. So some of you asked me to take this subject of taking over of the construction site after another contractor. Yes, it is difficult. Yes, it is more expensive. Yes, you need to go into the details re understanding what’s the problem with the construction site. All of my guests of previous episodes really highlight this necessity of jobsite investigation, they all insisted on asking questions and gathering the information in order to really understand it, and being able to and give the best working solution. So this time, even more important task, gathered all this information, understand the situation understand the problem and understand why the previous contractor made a mistake. It’s so absolutely so important. Before I dive into all this details, I would like to just say that I’m not going to deal with the business part of this of this problem. So I’m not going to discuss how to sign a contract, I’m not going to tell you what kind of price you should give to your client in order to re inject the crack. But I think that we all agree that this time this injection should be more expensive than the first one. Sometimes the problem is the price because first, at first, the investor found the cheapest solution, the cheapest contractor, and that is why they were not well skilled. And this was the main reason why the crack is still leaking. So now it is you you’re about to re inject this crack. And so your price absolutely has to be higher. If you listen to previous episodes of the of this podcast, it was the interview with the representative of the Forum on Injection Technology from Germany from Cologne. From this episode, we learn that this kind of repair should be definitely should be the subject of the design of his project. So well, they say they suggest that the contractor himself should not make any decision on the technology. However, we all know and we are all the time asked by the investor by our clients to come over on the job site and suggest a solution to a given given problem. So even now that we should have the designer to give the specification the technology we are all the time asked to do it by ourselves as a contractors. So yeah, that’s it because obviously the investor wants to have the problem solved. quickly and the cheapest possible way. So, like, we have this this expression, the best time for this job to be done is yesterday. Now they want to have it done yesterday, not even not, not today yesterday. Okay, so let’s start today’s topic, we are on the job site, we see the crack, we see the crack that has been already injected. So, we need to ask ourselves the question, what is the reason that the crack leaks again, is it the reason that the crack has been injected improperly? Or the reason is that there were some forces that destroyed the ceiling. And then we really need to know this reason, we need to understand that the cracks are most often formed at this very moment of setting the concrete. So, most likely, and there another leakage from the same crack is caused by the applicator, the former applicator, what does it mean that the crack is leaking? It means that the crack has not been filled with resin injection resin properly, it hasn’t been filled fully. So, there are some gaps empty spaces in the crack that let the water going through it. Right. This is the reason. So, our task at the moment is to find out the mistakes and understand why previous contractor didn’t fill the crack properly, what went wrong? And I will give you some points, some questions to be asked, asked and answered in order to understand the problem that has been done before. And so, our task at the moment is to feel fully fill the cracks with new resin. Let’s do it. Okay, so as I mentioned, just a second ago, we see the crack, what do we say? We see the crack itself on the surface of the concrete, no matter if it’s a wall or a slab? We see the crack, right? And we see the liquids. Perhaps we even see the water coming through the crack or the water drops. Going out of the crack. So like, yeah. And what do we see even more, so we see old holes, drilling holes, perhaps we see even old packers that are still in the hole. So if we see old packers, it’s even better from for two reasons. First reasons being that we can see the angle at which this hole has been drilled before. And the second thing is that there is a packer inside the hole. So the hole is closed with the packer. So when we are going to inject using new Parkers and new holes and new Packers, then the resin will not be able to flow out of old holes. If we see only holes, then it’s a little bit more complicated to find out the angle and the angles of the old holes, but it’s absolutely necessary to know the angle. What do we see, we see spacing between holes. And we see the spacing between the holes and the crack. And we need to know it exactly we need to measure it and we need to find out it we need to compare it to what we know about how to inject into the crack because this will give us information after you collect all this data about the spacing holes, angles, diameters of old holes, everything. So after you’ve done all this jobsite investigation about how this crack has been ejected before you need to compare this information With new calculation about how this crack should have been injected correctly, and the most important thing you need to know absolutely no 100% is the thickness, the thickness of the of this concrete of this concrete wall or this concrete slab no matter what it is, but you have to know the thickness, because this thickness this information about thickness gives you the possibility to calculate everything else, because the spacing between walls will be half of the thickness, the angle should be somewhere around 45 degrees. And of course, if you start to drill around half of the thickness away from the crack, all this information is absolutely necessary. And you have to compare it because this will give you the answer what have what might have go wrong before if there were no injection packers in holes. And then it will be harder, I guess this is the more common situation, because usually you know, the packers are removed just after injection 4 days after injection. So, when you are called to repair, re inject the crack repaired once again, then it’s like three or four months later. And so, we can expect that there will be no injection packers in the holes. So, it is a little bit harder, why you need to drill these holes once again carefully, you need to drill it like they were drilled before because you need to understand what is the angle, what is the original angle and you need to understand what was the diameter of this hole before because in most cases, you will have to use a bigger drill bit like if there were holes of 10 millimeters, then now you will have to use 14 one three millimeters diameter of the drill bit. But if there were 13 millimeters, then you might try to use the same once again 14 or a little bit more like I don’t know 15 or 16 millimeters diameter between because and then you of course you will have to use bigger Packers. So, you drill 14, 14 Packers 14 diameters you 16 years 16 Packer 16 millimeter diameter of Packers why because in most cases when you have to re- drill the same the same hole then you will destroy a little bit the internal walls of these holes and then then the amateur will be bigger and you will not be able to install the same Packers as as before. So, this is important you have to have different different Packers different diameters of Packers because you never know what Packers were used before by the other contractor after you collected information of thickness of this concrete being injected, and you know the spacing and angles of the holes being drilled by the previous contractor, please draw a diagram of the concrete cross section you will see this crack you will see the old holes and its angles and then you will be able to determine from this cross section from this drawing how deep the holes all holes have crossed this crack. And I can assume that they cut it quite shallow meaning close to the surface of the concrete below half of the cross section half of the thickness of the cross section and that means that this is the mistake. It means that the feeding place where the old resin were about to go from the holes into the crack, they were too close to the surface, they weren’t in the middle of this concrete being repaired. And that is why the resin were not able to feel the crack correctly and perfectly. Once again, we are talking about the situation of the cracks being formed and the moment of setting the concrete. I’m not discussing the crack the day where my my by the overloading the concrete, because, if if this is the case that there is an overloading of the concrete, then the cause of showing new cracks is not removed. So, the problem is not solved, we aren’t just talking about this situation that the cracked appeared the very beginning. And we are sitting this once again, because someone else’s made a mistake during the injection process. Yeah, we are collecting all the information and try to understand what mistakes were made before in order to make reinjection of this Crux once again and to fill it. So, we have discussed angles, we have discussed spacing between holes, and the number of holes per one running meter. And all this is made, all this calculation is made is taken from the core principles of crack injections that we know the spacing between halls is half of the thickness angles should be around 45 degrees. If the hole were drilled, more or less half of the thickness from away from the from the crack. And then we have this diagram drawn drawn diagram, we can compare what the situation that should have been with the situation we see on on the job site. And in most cases, we see the difference in depth. The difference is sometimes it’s huge the difference in that where the holes should cut the crack, and it should be it should cut in the middle of the cross section. But in most cases, the the crack is being cut by the holes below half of the cross section. So our task is to drill another holes, new holes, more holes, because we need more feeding points per one running meter. So after I made this list of things that should be collected, or this list of the information should be collected. Let’s dive into the another list. A list of things should be done step by step in order to inject the crock properly. Let’s do it. First of all, we need to take care about old Packers. Hopefully they are still there in house. If if they are there, you’re lucky you don’t have to remove them. You don’t have to drill. Once again, the same holes, you just keep them because they will make the holes being tight. And you won’t lose any resin through old old holes. That’s great. Yeah, you’re lucky. If there are no Packers, unfortunately, you have to drill the holes, you have to drill the this parts of Packers that are still in the holes. You need to install new Packers, as I mentioned before, most probably using bigger diameter new Packers being an amateur. That’s first first step the second step is you calculate the spacing between New holes, spacing between New markers and spacing between New packers and crack. And you drill new holes and you drill new holes even more than then if if you are about to inject this crack for the first time, at least 20% more cracks. So usually you would you would drill let’s say six to eight holes. Now I would say at least 10 to 12 holes per one running meters. Of course you have to calculate it according to this rule of the spacing is half of the thickness of the concrete but the more the better because you need more holes more feeding points of resin okay. So, after the holes are drilled I mean new holes are drilled and cleaned you need to cut the resin and close it with mortar apoxie mortar or cementitious mortar in order to prevent the resin to flow out of the crack during the injection process. Because we know for sure that the resin will try to fill out flow out from the resin and even more than usually because there are more holes being drilled and there is resin some of the resin altra resin is still in the in the crack. So, it is more difficult to fill this crack with new resin were in the situation where the old ultra resin is still there, here and there. It’s still there. So, he knew resin will have difficulties with flowing for the crack. In the other words you will have huge difficulties in driving the resin into the crack. I just mentioned old resin it’s great if you could collect the information what kind of resin has been used before in most cases it was Pugh by threaten, but what kind of resin was it resin that creates foam forming resin or resin that does not create any any form or almost any fault. So the more you know about the repairing material that has been used before the better and speaking about your resin you should really use low viscosity peel based resin and they’re always the butter, but what I mean low is around 50 to 5560 milli Pascal seconds, some producers will tell you that low viscosity is around 100 and 50 million Pascal seconds, but I don’t consider this kind of viscosity being low. That’s the first point the second remember that you are here to re inject the same crack once again you have to have you have to use really best possible injection material injection resin you cannot use resin that looks like honey on the job site. So, you will use the lowest possible around 50 or even lower viscosity resin and you will make the smallest possible amounts around up to 150 milliliters because you will you you need to use fresh resin if there is situation and then the old holes are drilled to narrow or simply there are bad angles and taken and the hole past the crack close to the internal surface of the concrete. And then we know that our new holes should be drilled much deeper and lighter during the injection if we see the resin coming out of old holes that it means and there’s difference in height between old and new holes in height when the holes are cutting the the crack. So, when there is this difference and you we see the resin coming out of the old holes, it means that we have filled the crack the space I’m not sure if I made myself clear and just before So, let me let me go into the details into these details. Once again. There is the difference in height between the new holes penetration point into the crack and the old holes penetration point on the crack and if we inject this difference because We see a resin coming out of old holes, then we have at least injected this difference. So we can conclude that resin is in the crack, then we go further and inject more resin into the holes to fill the crack in this part of the crack that is external to us, I mean, that is more far away from us. Yeah. And if we, if our new holes were drilled in this way that they caught the crack even beyond the half of the thickness of the concrete, and we still see the resin coming out of the crack, then we know that the crack is filled really very well. And we can expect that this time the injection process is, is being done correctly when re injecting the crack. And we drill holes close to the external surface of the crack, meaning very high as a kind of checking point and to see if we’ve fully filled the crack because we’ve we will run the injection using the regular holes and Packers installed in these holes. And if we see the resin flowing out of this holes that are drilled close to the external sulfur surface, and but still cutting the crack, then we know that the crack is really fully filled. I mentioned this many times before, including my online webinar. But once again, you are going to use open Packers. So what I mean by that is that you will attach nipple only to this Packer you’re about to inject all of the rest packers are going to stay open because you’re going to observe the resin being driven down the crack you’re going to the iterate the the crack and you need this absolutely crucial information about where the resin is in the crime, I have to say that during the injection process, we will have leakages rather than leakages everywhere. It will look like almost all the resin is flowing out of the crack itself. And some part of the resin will flow out of all halls after all Packers even though the Packers new packers are installed in the same holes. So, even though you see that you are losing this resin, you have to remember that some part of the resin goes exactly where it should mean into the crack and it feels the crack and it goes into this resin is driven into the cracks. So no matter how much resin you lose, you inject this because you know that you have installed, you have drilled proper holes, and you installed proper Parkers. And now you’re running the injection no matter what you know that there are old holes in all that there is old resin into in this crack. And it’s not that easy to drive the resin into the crack, but you have to do it because the there is no other way then and doing this. So in the end, we can say that reinjection the crock takes more time, it takes more money because you drill more holes, you install more Packers, you use more resin than usually it has to it simply has to cost more. And but it gives you the opportunity to build your own brand because you are the one who is capable of re injecting the crack who is capable of taking over somebody else’s job site. And yes, there were years that I have been re injecting more cracks then and then you know, injecting the new ones. Perhaps it sounds funny, but there was a time that I was considered to be the one who really fixed these kinds of botched job sites. And not only when it comes to crack injection also for one company To expansion joint and other types of injection. Yeah, I just remind myself that next week we are going to repair re inject. Yeah, re inject the expansion joint that has been injected last year. And it’s, it’s leaking. And so, yes, I will take pictures, I will exactly and make notes. What we have done in order to repair this expansion joint, and the plan is that we are going to remove old accurate gel, and we are going to inject a new one, we will clean the hole on the internal walls of the of the expansion joint. I will make another episode explaining this technology step by step. So, yeah, I hope I hope that you will find it interesting. All right. So, that’s it for today. I hope you like it. I just wanted to say that it wasn’t easy to make this episode because I wasn’t reading anything I was just making, you know, I just made some notes. Some bullet points what I wanted to mention during this podcast, and I’m just saying this like I was talking to someone and having coffee. In fact, I had two coffees during this recording today. I hope you like it. If you have any questions through this technology, please feel free to let me know. And as usual, I hope you will tune in next time. Bye bye

+ Click to view entire transcript

– Click to collapse