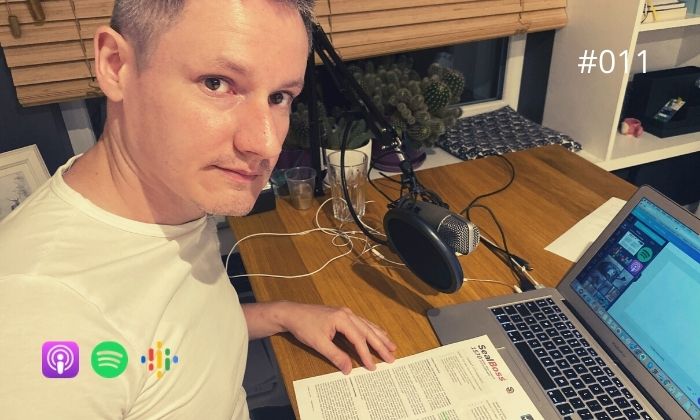

Taking the ‘Voodoo’ Out of Concrete Injection With Chris Coderre from SealBoss

A big problem on job sites is that some concrete repair contractors aren’t methodical enough in applying proven processes and technologies. This leads to sub-optimal execution and customer dissatisfaction. And this just makes a bad name for the dedicated professionals among us.

The key to being the kind of contractor that gets repeat business because they use proven methods, technologies, and processes is to leverage the information that can be found in well-prepared datasheets.

So in this episode, we get into how you can use this data and insights to demystify concrete repair and take your concrete injection game to the next level.

And remember, TDS are for free no matter what! It allows you to find the right solution on your job site.

From the #011 episode of Concrete Injection Made Easy podcast you will find out:

- that you can learn injection even for free from the technical datasheet

- many chemistry manufacturers, including SealBoss, have prepared injection guides that are free to use

- each chemical manufacturer has a specialist in his team, contact him and consult your idea for repair

- listen to podcasts and subscribe to the newsletter, this is another portion of knowledge from our industry

- a well-written technical sheet will allow you to choose the right resin for your situation at the construction site

- only a well-analyzed situation on the construction site will allow you to prepare the appropriate repair technology

- the cases discussed in the interview come from real construction sites, did any of them surprise you?

10 Core Principles for Crack Injection

Hint: 90% of engineers and applicators don’t know them.

Tuday’s Guest

My guest, Christopher Coderre, Technical Sales Manager at SealBoss Concrete Solutions, West U.S./West Canada, has loads of experience in providing solutions to concrete repair professionals. He and the team at SealBoss have distilled decades of experience and put in into technical datasheets that are available for free.

I feel this is one of the best conversations since the podcast started. I know I say this every 2 weeks, but it really is. When you listen to Chris, everything becomes clear, simple, and organized. Is there anything you did not understand after listening to this conversation? You can hear here great experience and the ease of transferring knowledge.

If you want to contact Christopher, this is the link to his account on LinkedIn, Christopher Coderre. Please mention that you’ve heard this interview in your inviting note.

Resources

TDS of an injection resin SealBoss1570 that we discuss.

SUMMARY KEYWORDS

resin, injection, datasheet, people, job, reaction, crack, leak, leakage, water, guidelines, substrate, sheet, product, materials, educational aspect, viscosity, pump, technology, seal

SPEAKERS

Mateusz Furs, Christopher Coderre

Christopher Coderre

Our experience over the decades has enabled us to prepare and let me tell you it comes from it comes from being on jobs it comes from seeing things go good bad and everything in between the where the to where the distillate of those experiences the the you know the aggregate product of those experiences as it gets put into for example, a datasheet is going to be very helpful to the end-user,” “That is invaluable. There’s so much that they can gain from that experience by having somebody convey the details and the methodology and what is required. And then when they see it work like they have, that’s when you take the mystique and what I like to call the voodoo out of it. And it’s very tangible, very technical, very proven work and systems that get employed,

PONIŻEJ WKLEJAMY ROZWINIĘCIE

Mateusz Furs

I’m telling you. You will love this conversation just like I do.

My guest, Christopher Coderre, Technical Sales Manager at SealBoss Concrete Solutions, has loads of experience in providing solutions to concrete repair professionals. He and the team at SealBoss have distilled decades of experience and put in into technical data sheets that are available for free.

So in this episode, we get into how you can use this data and insights to demystify concrete repair and take your concrete injection game to the next level.

Mateusz Furs

Hello, Chris. How are you doing?

Christopher Coderre

Mateusz, I’m doing fine. Thank you. Appreciate it. How are you?

Mateusz Furs

I’m doing awesome.

It’s 5:40pm in here in Warsaw, Poland. What’s the time at your place? Can you say it?

Christopher Coderre

it’s 8.40 pacific standard time here in the United States in California.

Mateusz Furs

SoI assume that you are drinking your second coffee.

Christopher Coderre

Still on my first about halfway down, but yeah, absolutely.

Mateusz Furs

All right. I had four coffees today. So this time I’m staying with water and a tea.

Christopher Coderre

There you go.

Mateusz Furs

Terrific. I think it’s it’s too late for the fifth one. today. So yeah, enjoy your coffee.

Christopher Coderre

Likewise, great.

Mateusz Furs

I had invited you for this conversation in the podcast called the concrete injection made easy because we have a great topic today. But before we dive into this, can you tell our listeners about yourself about your company a little bit?

Christopher Coderre

Sure, Mateusz, not a problem at all. My name is Chris Coderre. And for the SealSoss organization here, I manage the western region. So I have responsibility to maintain and build the business and train and educate the contractors on the proper use of our materials in 13 states. And I also handle the same set of responsibilities for Western Canada, in both British Columbia and Alberta. And occasionally, I find myself down in the southern hemisphere, in support of our distribution partner in the country of Australia. So yeah, that’s that’s what I do for the organization.

Mateusz Furs

It seems that you travel a lot.

I well, when pre covid Yes, I was, I was on a plane at least once a month, sometimes twice in support of our distribution partners and projects as well, where contractors have a need to receive the proper training to be able to get their jobs done correctly. Yeah.

Mateusz Furs

Well, yeah. Okay. So at least one time a month in the plane, visiting your clients visiting your sales rep, your coworkers. Yeah, and all connected to injections or something else as well?

Christopher Coderre

Both. So one thing about our organization is we have several product families that we offer. Certainly, pardon me. Certainly the focus is the waterstop injection resins and systems. We’ve been at that game for well over three decades. And we have a nice breadth of product lines and equipment and accessories. But yeah, we also have some other lines that could require training and myself in a certain area outside of our home base here in Santa Ana. And so yeah, it’s it’s not always surrounding waterstop injection, it could be structural epoxy injection, it could be floor repair. Yes. To just name a couple others. So yeah,

Mateusz Furs

yeah. Okay. So I can tell you a quick story about how I came across the SealBoss brand. It was the, you know, like, let’s say that I know about your existence for a couple of years, even though I’m from Europe, so we don’t have the possibility to to buy our products. At least I didn’t use it I have to admit, and not even once. But in the beginning of this year, I was asked by my Polish client that has some business in Australia to help them to choose the right product and to you know to produce the whole technology of injection the sheet pile walls and they told me that they are going to buy resin over there in Australia so they are not going to buy it directly from me in Warsaw and then they are not going to take it you know to to ship it to Australia. I sold them 1K pump and my 1K pump from Warsaw was shipped to Australia. So I felt like I was sending a Pathfinder to Mars. Really, because it’s still there, it won’t come back like Pathfinder I really doubt that they are going to can bring him back ever back to Earth. And you know, it was supposed to do some job over there so exactly like the this Pathfinder analogy is it fits perfect. And then I was asked to prepare this The solution the technology step by step I did it and in the end I had to choose the right resin and I was given like two or three different manufacturers to choose from. And I have chosen the SealBoss 1570 resin. And WHY? And this Why is exactly the topic of our conversation because this all the information I have found on your technical data sheet, you call it the product datasheet But anyways, exactly the same. All the information I needed to find I have found and I could imagine how the resin works even without touching the resin. And then when the job was done, I got the feedback from the from this guys that they were running the injection The the resin I have chosen and I told them step by step what to do performed exactly as it’s supposed to. So our topic today is what makes a data sheet a good one, to help you to sell the product and to help me as an applicator to choose the right product.

Christopher Coderre

Yeah, that’s that’s a great topic Mateusz. And it’s one that we encounter here as a team often. To answer the question, let’s focus you asked what makes a data sheet a good one so that somebody can look at it, review it, analyze some of the physical property data that’s listed and ultimately make a decision on what resin is going to be chosen to perform the duties that the job requires. Our data sheets, what we what we strive to do in our data sheets is keep it as concise as possible yet as informative as possible. It’s it’s kind of our philosophy that if we need to have something that’s voluminous and multi page with, you know, data and data and data, that’s, that’s requisite, that’s fine. But when it does not have to be like that, we don’t really see the value in it. So ultimately, if we can format something in this, this has a lot to do with just the way humans behave as well in terms of their eye and how their eye gets drawn to certain parts of whatever is on a page. We like to try to keep our data sheets very friendly to the eye. Now, there are a lot of numbers and facts and figures, but we try to keep things organized. We try to keep things aligned physically to the eye. So that’s step one. Step two is populating the data sheet Mateusz with relevant information. So there are testing criteria that some engineers for reasons that a lot of times are kept to themselves and rightly so that they need to see on that data sheet. There are also the two or three aspects of resins physical properties that are on a data sheet that usually are focused upon immediately, reaction time being one of them, viscosity being another. And this is just in my experience, those two things are oftentimes just like I said, very, very much then immediately focused on to make the determination of Okay, based on this, for example, in a crack injection scenario, if you’ve got cracks that are very fine and very tight, you’re obviously going to want to choose resin whose centipoise is as low as it can be, so that you can drive that material deep into the substrate and get that reaction to occur deep into the substrate and Give yourself that integral seal that is going to be permanent. And it’s not just a, you know, a bandaid as it were in the industry, quote unquote. The other thing is, of course, the reaction time. When you have products like, you know, you’d mentioned a certain resin and this resin is is catalyzed, so there’s an extra chemical component that’s added to this base resin. Well, by adjusting the amount of that catalyst that you put into the base resin, what you can do is either cause that resin to react quicker or slower. And that becomes very instrumental when sealing off leaks as well because in an emergency type of a leak where the flow rate is very excessive, and you’ve got something that’s a bit of an emergency and character and excuse me categorized as such, you might want to maximize the amount allowable of that catalyst into that base resin so that you have a cut off type of a grount immediately. In other scenarios, where let’s say you’ve got a very thick concrete substrate, we find that being able to lower that amount of accelerator, obviously, as it’s added to the base resin is very, very instrumental in allowing that resin to be able to travel, okay, and allow it to find its distance into the substrate, and then react. So it gets into the deep, deep root cause of the issue. And that’s, that’s what we find is very important. So getting back to the datasheet, those types of things that are on there, so your reaction times and your viscosities and your percentages of accelerator that will lead to certain reaction times and production times. We find those pieces of information to be the most Paramount when when assessing a datasheet for specification on a project.

Mateusz Furs

So I see like from the applicators point of view, it’s looked like I knew quite well what was the problem? And I could I’ve seen this the same problem, say here in Poland. So, you know, I didn’t have to use so much my imagination to really understand what what is the solution, but then I needed to be sure that this resin will perform as I know, other producers products. Yeah. So I was looking for something that is similar. And then my situation was there was water leaking, but it wasn’t a heavy leakage. So, this resident didn’t have to be so, so fast and I knew that I’m going to use 1K pump so I needed the resin that is is going to be pumped using this exactly this, this equipment. As I know the leakage was in this connection. Between the sheet pile walls segments, so I did I know that I don’t need the lowest possible viscosity because the spacing to be filled were quite big. And so yeah, that’s it and then I knew that since there is quite warm over there I need to be able to add a little bit less this activator. So the resin won’t react too fast. You know, at the same time the pumps make this resin warmer while working. So this reaction times is going to be faster with this additional amount of, of heat and all of this information is necessary. to choose the right resin and then you just compare what you know and what you have on site with what you can find on the technical datasheet. Yeah, that’s it.

Christopher Coderre

Yeah, that’s that’s a very good, very good collection of points Mateusz and and I sincerely appreciate your willingness to be to be able to assess the condition. So our philosophy here, pardon me when we deal with any given customer or you know, as we work with our distribution partners worldwide, one of the biggest things that we focus on is the educational aspect of it. Here’s there’s a bit of a kind of a three step process. The first thing we encourage our new employees to get on board mentally is when someone calls in, there’s a good chance that the majority of the people calling in are relatively new to these technologies and these processes and these systems so Folks like myself and you and others in the industry, you know, we have the ability to kind of have at the ready, a set of answers that are probably going to be used multiple times to answer the questions on a daily basis that come in from our customers. But getting back to what you just described there Mateusz that is, that is the the essence of what we try to do and the educational aspect where the first thing you should seek to do is help whoever is calling it and so when you have the philosophy of how can I help this person, the next step is okay, based on their application, and based on whatever we can provide from our arsenal of total system solutions to include accessories and pumps and resins, what can we then pair with the application at hand so that we can give this a very, very good effort and have the outcome be successful and in this case, it would be stopping the unwanted leak, you know through the concrete structure. The very last step is the procurement. If steps one and two are fulfilled, it’s almost by default that step three in the procurement of the material will occur and we think that when you try to lead and flip things on their head a little bit and try to get the procurement to be the focus. It’s not really in this industry Anyway, what people want to hear and wants to talk about this is the beauty and I tell people this The beauty about what I do is I yes, I may have regional sales manager is my title and titles. Everyone’s got opinions about titles, that’s for another topic and another day, but you know, ultimately, if I can serve as As a solutions provider if I can help somebody first, you know, it’s that that procurement thing that’s two steps down below that that’s going to happen most likely. And then we hope so right. But this is a technical industry. This is a very procedure intensive industry. Which leads me to just another thing, if I may materials and that is sure, teaching teaching contractors how to employ these systems and making sure that they know the difference between hydrophobic and hydrophilic. When to use a water stop, when to use a structural high modulus, low viscosity epoxy. These are very, very important things. And I have to say, and I’ve touched on this on some of our episodes with guests that we’ve had on our podcast, making sure that the engineering community as well is aware of when to use what is so very important. So, yeah, I listening to what you said about, you know, seeing what you had in terms of an institute condition, and then being able to look at the datasheet and assess the information on that to make the determination that hey, this is the resin that we’re going to want to use. That’s, that’s fantastic.

Mateusz Furs

You know, when I was new to this industry, it was back it wasn’t so long time ago because it was 2011. I worked for the, one of the European manufacturers and I was training in Germany. And you know, they were putting this this one most important aspect is asking questions, asking questions, and once again, asking and trying to understand as much as possible all the costs of the situation. What will The cost of the situation the leakage of this crack or you know, concrete and damage and so on. And then according to this, you know, finding the best possible solution without understanding what’s going on on the job site and without asking questions to people that might have seen what happened or may have, you know, even to the people who might have made some mistakes it’s really really helpful. So without this we can only know painted and you know, without any other possibility to to really repair it. So I don’t know how, how does it look like on your market your place, but it is really often that I came to enjoy And I see a croc that was painted with some tissues, you know, something I don’t even know what. And then people are, you know, in shock, because this crack, obviously within amount starts to leak again. And they are telling me that, you know, they paid some money to have this crack repaired and it still leaks. So they don’t believe in the technology, yet don’t believe in injections. So this is my point, I share my knowledge and that is why I started the podcast to really convince people that don’t know injections at all, or they don’t like it anymore because they fail. They’ve seen the failure of somebody else’s work. Yeah, this is like my main goal. Because if I managed to convince people, that this injection really works It makes that this whole pie of the whole market of the injections will be increased, it will be bigger and bigger because the more people understand that it works, the more people will really try to, to use this advantages of what have the advantages of injections, solutions. So yeah, I think we managed to do it on on the job site, I told you at the beginning of our conversation, and because they actually I can tell you that they were really surprised that I didn’t have to go there and see the situation. And I was still able to give them the right solution step by step, including to you know, this this choose of the of the resin.

Christopher Coderre

Mateusz, That’s that’s something that I can’t I can’t agree more. I think it’s wonderful that you pointed that out. We find ourselves in that situation quite often earlier on in the podcast, we talked about our I mentioned, the territory that I cover, pardon me. And one of the one of the key aspects of it, we touch on this educational aspect of it again, as I travel on the western side of the US, we’re very distribution heavy in terms of the model that we try to employ and grow in the market with part of that, a very core part of that is when I land in any given geography, I don’t care if it’s Portland, or Seattle or Denver or Phoenix or Vancouver, Calgary, it doesn’t matter. What I try to do is get my distribution partners at least on a level, where as the questions come in, that are very general from people who are new to this kind of injection technology that those individuals at our distributors or in our distribution partners ships, the people working the desk to people out on the streets making the calls and you know, boots on the ground, have a baseline level of knowledge to where they can solve the problem, go to the job site and then the most important part is the support. As I speak to you right now, and you’re in Poland, and I’m here in the US, we are thousands of miles apart yet technology enables us to communicate. In that same vein, I have used personally FaceTime teleconferencing, Skype, just to name a few technologies to be able to convey the technical details, the very nitty gritty as it were, of what one needs to do to be successful on a job. And I can’t tell you how much I echo your sentiments about taking the taking this mystique of injection Just reforming the game. There are a lot of tenured veterans to grouting as a as a whole that have a very skeptical view still about chemical grout injection. And I encourage anyone listening listeners out there, I encourage you all and implore you to be more open minded to the people that take the time to learn what it is that’s necessary for the applicators to do in the field. This solution and these technologies work I’ve seen it first hand and when you prove like in Mateusz, as you’re saying, when when the job gets done and done right. There’s a very good satisfaction and a very good feeling that comes from that as a as a manufacturer’s representative as a technical representative. And again, every job is different. Let me be very clear in saying that, yes, there are smart ways to attack big leaks. And we have done that I’ve personally done it and it’s it’s very rewarding. However, some of the smallest leaks sometimes can be very challenging. Yeah, yeah, very tricky. Actually.

Mateusz Furs

Actually, I have to agree. Sometimes it’s, it’s, you know, maybe it sounds peculiar, but it’s easier to stop a huge leak, then get rid of this, you know, the leftovers. This this little, you know, a wet what stays in the masonry. Yeah. So because it takes time to get dry of this masonry and people don’t understand this. And maybe there was some problem, like, not the problem there. The the mistake was made before, and no one knows it. And then this this, this wall stays wet. There’s no leakage, but it wet, and no one likes it as it is. So it’s easier to stop a huge league than to get rid of this small, small amount of water.

Christopher Coderre

Yeah. And to your point of being on jobs where people will complain about maybe having a cementitious part or something like that struck on a wall. I can’t agree more. I’ve been to several jobs throughout the years where I’ve gone to underground parking structures as an example. And it’s it’s it’s not funny, but it’s interesting as well, where you’ll see yes, those technologies that are that have been employed, and let me be very clear. Those I think there’s a very good opportunity for the different manufactures to start to have more synergy and to work together where maybe injection coupled with something like a cementitious application on the surface. That should be, I think considered more often by engineering firms in terms of the spec to be written to fully solve a leak problem if needed, especially from a standpoint of aesthetics. But going back I’ve even seen parking structures materials where attempts at injection have occurred, where Packer placement just as an example, is completely awry. Now, there are different means and methods that can be employed, but I rank I maintain and recommend only after the prescribed methodology. For example, what we have is a very nice spelled out it’s about an 11 page document. It’s our it’s our chemical grouting and leak stop guidelines where we get into To the very intricate details with respect to dimensions for drilling and all these other types of things that will give any installer the best fighting chance of being successful. Now, deviation from that can be entertained afterwards subsequent to the initial injection efforts if needed, but some of these out of the gate attempts that I’ve witnessed have just, It baffles me I scratch my head and I say, well, where did they learn and and it doesn’t make the installer, a bad installer, they could be very, very good with the best of tools, but it’s like anything else. You have to know how to use. I mean, if you don’t know how to use anything, um, you’re not going to be successful and that goes for machines that goes for automatic I mean, it could be anything in this world if it’s a device or if a system or a set of methods that need to be followed and adhere to deviation from that at the onset could lead to undesirable outcomes very very simply stated.

Mateusz Furs

Yeah, absolutely. So I can tell you that two months ago maybe one and a half we were about and we did it we were repairing the crack there were leaking and of course there was some previous attempt of injection we’ve seen some you know, holes old packers and old resin. And you know, this spacing between packerss was to bog, and the angles work was were terrible. You know, they were starting to drill exactly into the into the crock. So when they put the packer inside the hole, the packer was, you know, already Like, pressurizing the crowd. So no, no possibility to inject into the crack. So

Christopher Coderre

yeah, they’re important

Mateusz Furs

and so on and so on and so on. And then, you know, in the end this, the client, you know, hired us because someone convinced him that we are able to repair it. But in the end was like, come on, but we were you you are drilling. You are, you know, mixing resin, and you were injection so you were doing exactly the same step as the previous guys a couple of months earlier. So, what the heck, where’s the where’s the right? Yeah, there’s only one big huge difference right. Now the crack is sealed.

Christopher Coderre

Yeah, that’s exactly right.

Mateusz Furs

That makes a difference. But this rules you mentioned, we really followed the rules like we knew exactly. Where is the crack, we knew exactly what the thickness of this concrete slab, we knew exactly where to start to drill. We knew exactly at what angle we should drill to pass the old holes, to what spacing between the holes to keep, what kind of resin to use, how to mix it, and so on and so on and so on. And yeah, and you know, so I’m not very surprised that we managed to seal this crack. I’m surprised that this people who had hired us in the end, even seeing that the crack is sealed, couldn’t notice the difference between what we’ve done and what will what had been done before.

Christopher Coderre

Yeah, and I think a lot of that too Mateusz if you think about a building owner, or a client as it is very important if they’re open to it is to give them At least the chance to hear what people like us have to say about the technologies, how they’re employed, and what they ultimately do. And recently, no better example comes to mind I have the good fortune of being able to travel and support distribution partner of ours in Vancouver, British Columbia, Canada. And we sat with some folks that had a need for injection in a building and they just were completely brand new to it. And they had the luxury of somebody on staff that was going to be their installer so they did not have to outsource the the contractor. But having those three or four people in the room and having a big whiteboard in front of me where I can do my very best to explain the technology and show How it works, that is invaluable. There’s so much that they can gain from that experience by having somebody convey the details and the methodology and what is required. And then when they see it work like they have. That’s when you take the mystique and what I like to call the Voodoo out of it. And it’s very tangible, very technical, very proven work and systems that get employed. So I, I agree with you 100% Mateusz, you’ve got very, very good points in that regard.

Mateusz Furs

Okay, coming back to this the technical data sheet. Yeah, there are two more more points that you know, convinced me to choose this resin, not the other one. One of them is that there are of course, one component and only one component resins that react with water and then They stopped the water End of discussion. But what if there is no water? Like we had this leakages here and there, but in between there was no water. So, I didn’t want to, you know, taking the risk that some of the resin won’t react won’t react, if if it will happen that in some of this spacing, there won’t be any water to react. Yes, this reaction. So this resin we are discussing is or Yes, it says that it’s water activated, but at the same time, we can this component B that will ensure us that the reaction will take place if the water is not there, and this is exactly what they were they needed. Do you think that people you know see this this difference between this two kinds of resins that is if you know both of them are being injected using 1K pump, but the you know the reaction is different.

Christopher Coderre

We do see that occasionally Mateusz and I’ll say that the resin being spoken about here is is one that is hydroactive. But again because there’s an accelerator involved, what that accelerator does on a chemical basis is is kind of excites that base resin to want to come in contact with moisture and once that moisture it’s almost like a 3 ingredient cake we’re baking here, right? You’ve got your base resin. You’ve got your accelerator. Those are mixed together. Yeah, exactly. But those those that base in that accelerator are mixed together, and then pumped into the substrate. Then we need water. We need water Either the the problem water as they call it or the nuisance water, that’s our issue that we’re trying to solve. Or if it is dry, you can pre hydrate and we run into this quite a bit when you know construction schedules don’t always coincide with weather events or seasons. So any let’s take for example a very dry part of our world here in the US. Let’s take Arizona granted there are monsoons in the summertime but by general rule I mean the the namesake of the state is it translates to dry land. And so the idea is if you do not have that water, but yet you want to employ a resin like this, you can prior to putting your Packer in or even when your Packer is in you can hydrate so you can get a dedicated water pump or some type of conveyance means to get water into those drill holes and into the crack because the truth is Matusow very little water is now necessary. Once a little bit of water encounters that mixed batch of bass resin and accelerator that polymerization occurs. And once that chain reaction starts, it’s all over, you’re going to get a nice closed cell compression seal type of a foam to occur into form in that crack. Getting back to the crux of your question, the two different types. So in our world, we’ve got either hydro active or dry reactive, and there are different products that can be assigned based on what you would like to do. And this also ties into a point you’d mentioned several minutes ago with respect to some of the easier ones or where you’ve got big leaks and some of the tougher jobs or where you’ve got this residual moisture that’s starting to show itself over and over what we tend to find and the European method of specification that we have tried to do Make more prevalent here in the United States is where you attack any given leaking job on a two step basis. The first is getting what we like to call a bit of a cutoff grout. So something that is comprised of a base resin at an accelerator, those mixed together, you get them in a pump, you shoot them in, that would handle let’s just throw a round number at it, let’s say that handles 95% of the leak problem in Europe for decades, they have typically written specifications across the board to then include a subsequent follow up injection with a much more low viscosity type of a resin. Oftentimes this can be a two component one to one but with even a mixed viscosity of below 100 centipoise. That does not require any moisture. So what we’re doing there in that case materials is where fine tuning and making the last adjustments and filling in The very fine micro fissures and things like that within the substrate, so as to provide a complete seal. We’re getting in there, we’re doing our requisite duties to get that last 5% or whatever it might be sealed up and tightened up. So with respect to you know, what we see and people wanting to to different resins Yeah, it’s very advantageous for a material manufacturer to offer those types of product lines within their arsenal of offerings so that you’re not just a one trick pony. You can you can have other options available to you to come in and fine tune Does that answer the question?

Mateusz Furs

Yeah, that’s it. In our case, like even I said, the beginning that there is no water but we had the strong leakage and you know, so even though I wanted to make sure that this resin will react and that is why I have chosen this resin with an accelerator and the ground was filled with water. So, there was a huge amount of humidity around it. So, yeah, like I could, I can assure you that the reaction took place as it was supposed to. The the other point is that it says that in this part called the installation guidelines and that let me read this do not mix more material than the amount that will feel that will be pumped within reasonable time. And this is exactly what I like. Because I even you know, I encourage my employees to mix as small amount of resin as possible, and you know, like up to 200 milliliters which is less than a glass of water at one time. And why? Because when of course, when we are discussing the moment injection into the crack, where we do not need a huge amount of resin at the time because the crack is small and it takes time to really you know, inject this resin into the substrate as you explained a couple of minutes ago. So, if you mix this small amount the resin will stay fresh the resin will stay low viscous the time of reaction will be long enough to be sure that you will use the whole amount of of resin mixed on the other. Like taking this from this perspective like people makes two kg of resin What if something wrong with the pump? You simply loose this two kg of resin. And the reaction is faster because the more resin you use this reaction is faster. And because the temperature rises, it’s

Christopher Coderre

a reaction

Mateusz Furs

So this one simple sentence put over here, you know means that someone who has prepared this technical data sheet really knew and like it gives me the impression that this person knew what to do and this person was present during the injection on the job site. Yeah, this is like that. That was my my idea when I was reading this document.

Christopher Coderre

Well, we appreciate that that those kind words Mateusz and yes, just stating fact and by no means conveying, you know, any hubris or arrogance whatsoever. We’ve been at this for over for three decades this is this is our specialty This is our focus and by no means that we perfect but I will say that our experience over the decades has enabled us to prepare and and let me tell you it comes from it comes from being on jobs it comes from seeing things go good bad and everything in between the where the to where the distillate of those experiences the the you know the aggregate product of those experiences as it gets put into for example, a datasheet is going to be very helpful to the end user so touching on that theme again, overall this kind of, you know, common thread of a theme throughout this this episode is proper installation via the education and telling people how to do things. So yeah, the small batches at a time. Absolutely, unless an installer and again, everything every job is different. I will caveat but unless an installer has contact fidence that he or she can get large quantities into the substrate at a time without issues, then it’s very wise to make small batches. And for no other reason, then, like you, you were stating earlier, your viscosity will be consistent if, for example, they’re installing in cooler temperatures. If you have, let’s say, six liters at a time or something like that, it’s possible that the cooler temperature could start to cause the viscosity to increase on that batch that you have in that hopper.

So yeah,

Christopher Coderre

that that aspect of the datasheet is it does it conveys it conveys a technical savvy, if you will, as it relates to the proper install guidelines?

Mateusz Furs

Yeah. So in the end, we can I think we can agree that well written In technical datasheet, you know, helps me as a client as an applicator to choose the right product. And at the same time, the very the same time this this this well written well prepared technical datasheet helps you to sell it.

Christopher Coderre

Yeah, I think I think there’s a lot to be said for a datasheet that can be presented and again, I you know, in my opinion, it’s kind of we’re a very society these days is very instant gratification. There’s there’s not a lot of people who favor muddling through pages and pages and pages of documentation if you’re going to present something in my opinion and experience anyway, and this doesn’t make it true for everybody throughout the world. But in what I’ve seen, if you’re going to present a datasheet, for example, to a specifying engineer, they have a lot to do. They they are looking at multiple jobs at a time. They’re working countless hours. They’re there. Buried in details from job to job to job, the last thing they’re going to want to do is have to mole through, you know, 15 to 20 pages worth of a document now, excuse me if you present them with a clear, concise, formatted and organized document that they can quickly glance at. Part me to gain the knowledge requisite to to have the confidence to specify that product. That’s the game. That’s that’s to us what, what what we are trying to do. And we understand that and that’s why we try to do as good a job as we can on making in making the data sheets that we provide concise now, as a supplement to that. And to expand on that data sheet. We then offer something like our guidelines, and the guidelines, those are a little more voluminous. Those do have several more pages, but then at that point in time, the goal is to once somebody has digested and understood those guidelines materials with the datasheet plus those guidelines, and this, this rings true for the engineering community as well. You can get somebody up to speed, excuse me relatively quickly with a datasheet. And a guideline. So that the specification is written with confidence. And that’s where we erode some of that doubt. That’s where we take away, excuse me. That’s where we take away some of the mystique about chemical grout injection is kind of not being legitimate, where in fact it very much is when you can provide these these data sheets, these guidelines and educate and have people that can stand behind it. That’s that makes all the difference. And so yeah, I would agree with you on that.

Mateusz Furs

Yeah. Thank you so much. You know, I was reading this document during, you know, a day, so it was a night at your place. So it even, you know, saved you for from waking you up. If I if I wanted to call you to ask some, you know, additional questions. Yeah.

Christopher Coderre

We’re here at any time to help you out.

Mateusz Furs

Well, even while you sleep, Yeah, I know. That’s why

Christopher Coderre

they have voicemail. Right?

Mateusz Furs

I see. But I wouldn’t I wouldn’t get you know, this instant answer. And, you know, understanding this gave me the answer almost immediately. So, yeah, so, I think we have, we have shown to our listeners that, that a technical data sheet can be written in, let’s say, almost an interesting way. Good looking way. So it won’t be a waste of time to have a look at this and at least to understand what kind of pro product we are going to use and how to use it and what to expect when using a given product. So yeah, so we encourage everyone to really have a look at this and to understand it, and if something is not clear enough to ask questions to be sure that it won’t be too late, because when the water is flowing, that there is no time to you know, to read this. You have to read this before.

Christopher Coderre

Absolutely, yeah, very good point.

Mateusz Furs

Okay, and do you think we have covered everything we, we wanted? I think so.

Christopher Coderre

I sure do. Yeah. Yeah, absolutely.

Mateusz Furs

So if there are any additional questions We are waiting for it, we are going to answer all the questions. If I get some questions from our listeners, I will you know, send you the those so you can also help me to answer and talk to you soon. Because I really I am really convinced that we will be able to find some other good topics about injection is interesting. So we are going to find in other topics to to really have that and other interviews. What do I say?

Christopher Coderre

Wonderful Mateusz. Well, it’s it’s a pleasure. From all of us here at the team. We would just like to extend our thanks for having us on your show. We know that time is at a premium. Yeah, and we really appreciate that. So enjoy the rest of your week Mateusz and yeah, for our listeners, if there’s anything we can do to help out please let us know.

Mateusz Furs

Thank you very much for the conversation and for the time. All of us to you and your team, see you. Bye Bye.

Christopher Coderre

Take care. Bye bye.

Mateusz Furs

As I was putting together the audio of my conversation with Christopher, I was again struck by how valuable his insights are. There is so much great information to mine from this episode, so if you want to get a huge dose of knowledge about the concrete injection, this episode is for you.

So tune in, subscribe, and take your concrete injection business to new heights!

+ Click to view entire transcript

– Click to collapse