Concrete Injection Made Easy – Introduction

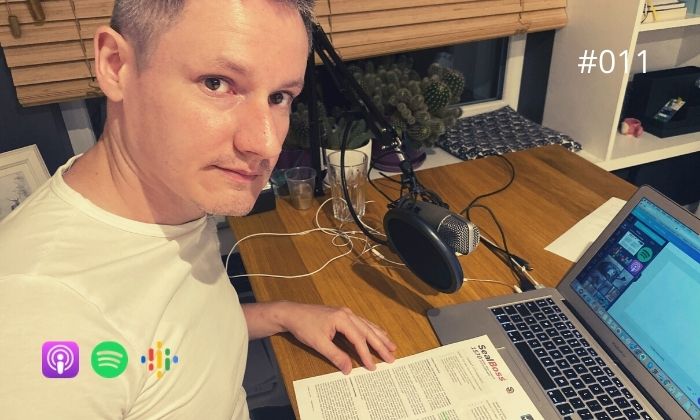

Tune in to the Concrete Injection Made Easy podcast, where your host Mateusz Furs shares his experience on injection technology and helps you get ahead of the curve with your business.

Discover how to pick and adjust the right resin or pump to the job to get the best, watertight seal on cracks and expansion joints…and expand your customer base.

Thanks for listening!

If you enjoyed this episode, please share it using the social media buttons you see at the bottom of the post.

Since 2010, Mateusz has worked in the concrete repair industry both as a product manager and as an owner-operator of contracting company in Warsaw, Poland.

In 2017, he started a blog on injection technologies and water tightening solutions like curtains, horizontal and vertical insulation, selection of suitable grouts, pumps, and packers.

In the podcast and on his blog, he talks about the injection technology in concrete, masonry, walls of concrete blocks, and stone as well as techniques for stopping groundwater outflow. He also dives into the principles of destruction by moisture and salts—and what can be done to prevent it.

He shares his experience of soil stabilization, lifting concrete, and making resin diaphragms in the ground so that you can apply the same techniques in your business. It’s a mix of solo shows and interviews from Mateusz, you’re not going to want to miss.

Hit subscribe and take your injection business to new heights.

001 Concrete Injection Made Easy – Introduction

Mateusz Furs

Listen to this sound.

If you know this sound you’ll know exactly what this is all about.

yeah, it’s a 1 K piston pump.

And this is the brand new Concrete Injection Made Easy Podcast … the very first episode!!

Hello everyone!

In the podcast, I’ll be talking about concrete injection and construction repairs.

If you are an engineer, … designer, … an applicator, … an expert … or a supplier of building materials then this podcast is just for you.

In this episode, I’m gonna give you one of my …best secret tips … that helps me to keep the mixed resin …low viscous … all the time.

It’s so important, especially in crack injection.

Make sure you stay till the end, to find out how you can use lower working pressure on your pump and still fill the crack.

And this is so important! But more on that later.

All right!!

I bet that there was a situation where you had a hard time deciding on your choice of resin.

Perhaps you’ve come across a situation where there was a high water table and it took a while to stop the water ingress.

Or maybe someone you know had a cracked bottom plate and it stopped the building process for over a month!

Have you ever been asked how to seal an expansion joint and found yourself questioning whether your own process is in line with best practices?

Do you want to know how to run your online marketing in a way that is tailor-made for your concrete repair or design business?

What van to buy and how to equip it?

There are three different locations to inject resin.

One, we can inject within the structure, meaning into a crack.

Two, between structures—so in expansion joints.

and three, external to the structure—so into the ground.

How to choose the right solution in a given situation?

Do these questions sound familiar? well, if so, you’re not the only one. In fact, all of us in this industry should be asking ourselves these questions.

I would like this podcast to become a place where we can all learn from each other and exchange solutions so that we can save time and money.

One of my first guests, Nick Chittenden, says that the more knowledge you have in your bag, the easier you can solve another situation.

I agree with this and I’m happy to meet people willing to help each other.

My name is Mateusz Furs and I’m going to run this podcast mostly as a series of interviews with experts around the world.

I’ll invite technology experts, construction company managers, entrepreneurs, designers, applicators, equipment producers. I will try to find out all of their business secrets so that we can all improve our skills.

If you have someone in mind that you would like to see on the podcast, please let me know.

Myself, I’ve been running a service injection company for almost 8 years in Warsaw, Poland.

Before this, I worked as a product manager for injections.

That job gave me a great opportunity to meet people and learn from them.

Learning is asking questions and then applying the new knowledge on your job site so that the knowledge pays off.

Suffice it to say, I’ve been in this business long enough to know how to get at some secret sauce when it comes to concrete injection.

If you have any questions, drop me a note on social media or by email.

Also please comment on this episode and get the discussion going.

And, if you like the idea of the Concrete Injection Made Easy podcast, please share it with your online community.

I hope I can get you as excited about this podcast as I am.

I know some of you already help others by running webinars and trainings. That’s great, I appreciate it.

I also ask you to provide information on conferences being organized for tunneling, concrete repair, equipment and so on in this industry.

Let’s enjoy, share and learn together.

I hope you are interested in joining the group of people already working hard and helping me to start this new podcast.

If you want to learn more, please visit

inblock.com.pl/podcast

This is where you can listen to the show, download the notes and comment on each episode with your ideas.

But most importantly it’s the place where you get information on the guests on my podcast.

Ok, now the secret of mine. One of the most important things, when comes to concrete crack injection, is to mix really small amounts of resin. It’s that simple! Ok, How small?

Well, I encourage my employees to prepare up to 200 ml of homogeneous mixture of resin.

Of course, don’t forget the mixing ratio of your product.

Here’s what you gain:

- number 1. low viscosity of ready mixed resin every time you mix a new batch

- number 2. small amount means the slower rising temperature of resin during reaction which means longer pot life and lower viscosity for a longer period of time

- number 3. low viscosity means lower pressure needed to inject resin into small width cracks

- number 4. lower pressure means safety on the job site both for you and the concrete being repaired

- number 5. using small amounts means minimum waste which means you save money

The best is that you can start doing so today. No additional cost required.

Just mix it in a small vessel so that it’s impossible to mix too much resin at 1 time.

If you also use a small pump hooper, then you’re really doing it right because

it allows you to notice even the smallest consumption.

Well, now you know the secret and all you need to do is go out there and give it a try!

Ok, once again, this is brand new Concrete Injection Made Easy Podcast, the very first episode!!

Please help me to share it and please subscribe so we can meet in a bigger group of great people every two weeks on Thursday.

The first three episodes, including this one, will be available all together on May 7, 2020.

In the second episode, you will meet Nick Chittenden from Master Builders Solutions and in the third one Stephan Delarue from Webac.

Thanks for listening, remember to subscribe. And I hope you tune in next time!

+ Click to view entire transcript

– Click to collapse