Let me ask you a question. Do you want to earn more, have more time, develop your business, sleep well without thinking that there may be leakages somewhere caused by your mistakes?

This is episode No 16.

When it rains, do you think that there will be more orders or that there will be more complaints?

Think if you are not afraid of answering the phone in heavy rainfall.

Isn’t it so that you want to increase your margin, but you still need to fix something you have botched before? Maybe these mistakes do not allow you to save any money?

Bugs and fixes still preventing you from building a reputable business or trusted brand?

You see, some problems are interconnected.

Does no-one want to work with you? So what do you do? Do you drop the price?

But when you lower the price, you attract the wrong kind of clients, who will try to pay you less, some won’t pay at all.

Remember that if the price or the value of the job is low, you’ll invest all money just to finish the job, and, as I said before you will not save anything.

Sometimes the price may be so low that one way to earn at least a little bit is to inject less resin, but if you inject less, there’ll be a claim, and you will have to rework it.

Reworking steals your time. Lack of time is one of the biggest problems all around the world but if you have no cash to hire someone to help you, this can be the end of your business.

Poor execution and bugs keep you from increasing your prices because nobody wants to pay for poor quality?

Remember that in our industry, the most important way to find new orders is customer recommendations.

Please keep in mind that you will get recommended only when you really solve somebody’s problem. This is the case the client is willing to pay more for that peace of mind and experience you bring. And this is the only way one customer can recommend you to another one. So, are these customers calling you? Hope you already know what I’m talking about.

And on the other hand, there are companies that definitely have a great brand on the market. They are known for still getting great jobs, executing them correctly, and earning money. They are very effective in what and how they operate on the market.

They have a group of regular clients such as developers, general contractors, and property managers.

Imagine that you run a company that has permanent employment, works among good, paying customers. Being an owner of such a contractor company you constantly earn, and you can constantly develop your business.

Imagine that you don’t have to worry about complaints, because you have so few of them because you can spend enough time on the job site to do the job in line with industry standards. Imagine that you don’t have to worry about hiring because customers are lining up. You are recommended in the market. Your brand is recognized.

So now there is a big, important question of how to change from a bad situation to a positive one.

So the question is how to move from the current situation of constant trouble and struggle to survive to the luxury of choosing the best customers?

From lowering the price to just get a client, to working at higher wages with people who pay you more because they know you’re worth it?

From a situation of enormous stress and restless sleep to running a business without a daily struggle?

From the situation where there is no cash on the company’s account and the lack of financial liquidity to the situation when you raise the salaries of your employees yourself because you can see that they do their job well and effectively and you just can afford to pay more?

Imagine that your higher earnings allow you to hire better employees and train them even more.

So how to transform from the situation of huge trouble to the desired state of running a successful business?

My solution I want to share with you is that I have started asking myself these 7 questions (and answering them of course) and it became my solution.

It allowed me to earn more, to acquire better clients, pay on time, pay my employees more.

Remember, this is the process of a change for yourself and your company. These questions first will help you have much fewer mistakes on the job site.

Later you will notice that more people are willing to recommend you and in turn, it will allow you to increase your earnings. Higher earnings will allow you to buy some more time. Once again, it’s a process. It will not happen overnight.

My solution is proper probing questions that provide insights into the injection technology process.

If you run a pressure injection contractor company you should spend more time preparing for each new project.

Especially if you do not have time and your business is far away from your dream one.

So here we go, the first question.

question 1: identify the construction type

Is it pre-fabricated concrete slab construction, concrete, reinforced concrete, brick masonry, concrete block masonry, and so on?

This will give you various types of information on how you’re going to drill, what kind of technology 1K or 2K it is going to be applied, Is it going to be curtain injection, structural injection, or a crack injection?

acrylic gel, PU-based, or epoxy resin

The knowledge of what the structure is made of gives you a huge amount of possibilities to be used.

Your client may not be able to recognize this. So you will do it yourself for the good of both of you.

Most probably you will visit the job site to get these answers.

question 2: location of the structural failure (is it above/below ground)?

This will give you information about how accessible it is.

It will help you identify the resin type to use and the repair methodology, help estimate costs more accurately, help you identify the target technology, gain a more comprehensive understanding of the demands and features of the job site. So as you can see a huge variety of different kind of information.

question 3: specific locus of the failure: in the structure, between structures, external to the structure

Is it a crack, an expansion joint, a structural leak, an erosion of ground around or under the structure?

What kind of info do I expect to collect?

kind of preparatory work to expose the failure (excavate?)

type of injection system,

type of resin,

the reaction time of the resin,

the viscosity of the resin, sometimes it’s better when it’s higher in order to avoid washing out

type of pump,

injection lances or regular packers

All of this will help you select the optimal mix of procedures and technologies.

For example, if I know it is going to be an expansion joint I know that it will be a 2K system almost for sure with acrylic gel or rubber-like injection resin.

question 4: is the structure wet or dry?

what kind of problem exists with the structure? leakages? voids needed to be filled?

Should I inject epoxy resin to increase the internal strength of the structure or restore structural integrity?

I remember to use epoxy when the substrate is dry because it reacts and bonds to dry structure better than to wet.

By the way, I covered this topic on the 14th episode of the podcast.

question 5: if the structure is wet, is it only moist or is there water flow?

if it’s wet, you’ll probably use PU based or acrylic resins because they react in the presence of water or even this nuisance water can accelerate the reaction; if there is flowing water, the epoxy technical data sheets won’t let you use this kind of resin.

if the water is flowing really fast, you should consider higher viscous material.

question 6: is the purpose of the repair to waterproof, reinforce the structure, or entirely restore structural integrity to its original state?

the answers will tell you not only the technology you should use but what you’re responsible for when you sign a contract;

the contract says what kind of remedial works you’re about to run and you have to really understand it;

there’s a difference when you say you’re about to run an injection without putting there on paper expected result

than if you’re running the injection to water-tight the structure.

I can tell you an anecdote here:

elevator shaft. They put in the contract that I’m responsible for waterproofing up to 1.2 meters from the bottom of the shaft, but I didn’t seal the whole area of the walls and the bottom of it.

I was just sealing the cold joints; this kind of contract says even if there’s water coming from elsewhere, from places I didn’t address, I’m still responsible for these points; I didn’t realize what I was signing up for / what I was committing to;

We can call it that I have been saddled with additional liability; I repaired the leakages and now it’s dry, but if it leaks, I’m responsible.

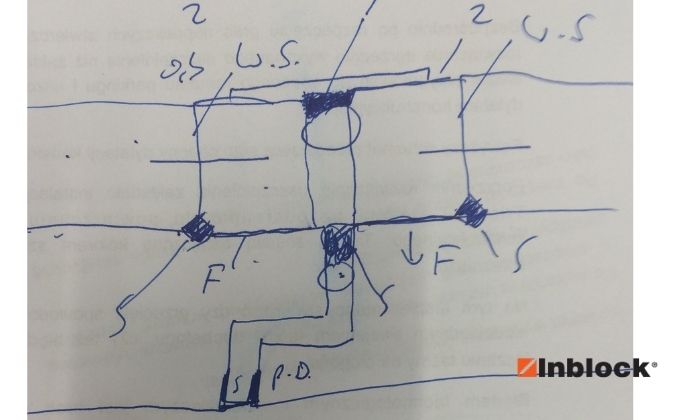

And finally, question 7: Do you document the problem area with photographs, notes, drawings?

Remember that preparing your own documentation will help you see the gap and notice things that are not immediately obvious;

Perhaps it may sound ridiculous but you really don’t know what you don’t know until you draw it out;

remember to take photos from a wider angle so you capture the context of the problem area.

This expands your ability to plan the repair, let you properly expose and secure the area around the repair to conduct the repair more effectively; otherwise, you’ll end up spending more time on the job site than necessary.

All this information is critical to level up your efficiency, and it costs you nothing but a bit of preparation and time to collect the data and think it through.

Your higher efficiency will transform into a lower amount of claims and this transforms into lower business costs, which will increase your profit margins and, ultimately, will benefit you.

If you do this, you’ll do your job better, your clients will notice this and your reputation will grow. You’ll then get more queries from potential clients and you’ll be able to pick and choose your clients.

I even say that my price, which is higher, is never so high that it can’t be paid because people are confident that I’ll solve the problem.

Repaired structures allow my clients to earn more.

E.g. Parking spots that are rented, the more spaces are rented, the more the owner earns, so it’s in their best interest to rent as many as possible.

Another example, a dam that produces electrical energy. The more water flows over, the more electricity is produced. Owners want as much watertight ground and structure so water doesn’t flow from where it’s not supposed to.

If you know how to bring this construction back to be used according to what has been designed, you let your client earn more, and your job pays out almost immediately.

As you can see, some investments payout within days, so the owner doesn’t lose money having not rented spots.

Even more, when the construction does not lose its value.

If you do this and ask these questions, it benefits you and your clients. The only thing is you can’t be afraid of asking these questions. if you do it, you’ll increase your effectiveness for free.

if the job is done correctly, then it’s really easier to have everything else in place. You’ll have more time to do also other things.

Can you see that all these points match exactly the desired situation I described at the beginning?

Now you are these 7 questions away from getting your contracting career to a new level by increasing your efficiency and building a personal brand.

Just note these or download the pdf file and start working in a smart way.

And one more thing.

I just started a survey on the construction repair and injection market.

I am asking you to fill it and help me help others.

These are only a few questions, most of them ask you to choose the best answer describing you.

Thanks for your survey deep insights and I hope you tune in next time.